North Texas Plumbing proudly installs PRECON Environmental Products concrete grease traps manufactured in Azle, Texas.

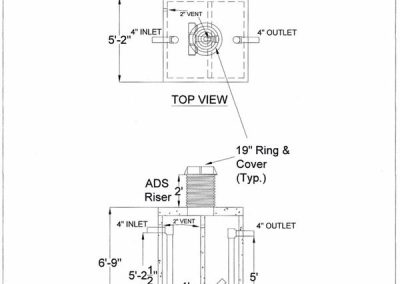

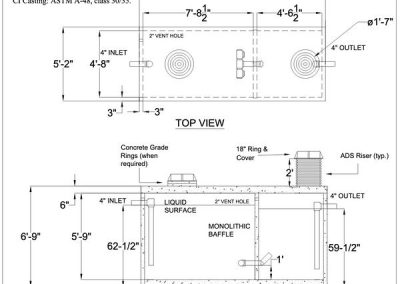

- 3500 SERIES ~ 500 GALLON GREASE TRAP

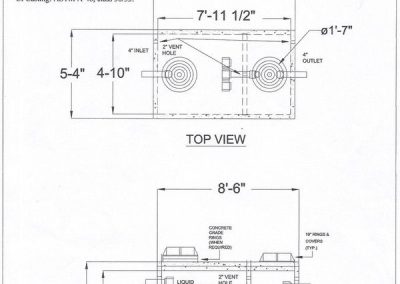

- 3500 SERIES A ~ 1000 GALLON GREASE TRAP

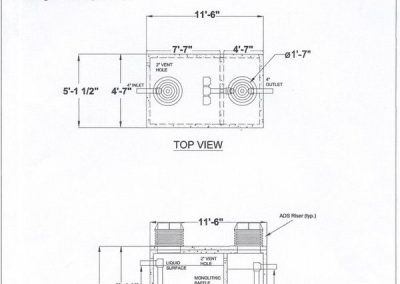

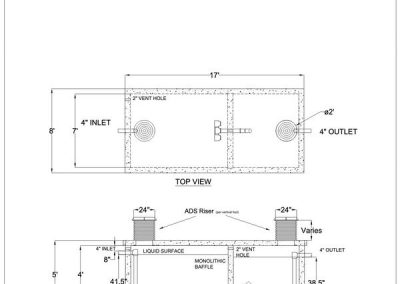

- 3500 SERIES ~1500 GALLON GREASE TRAP SINGLE BAFFLE

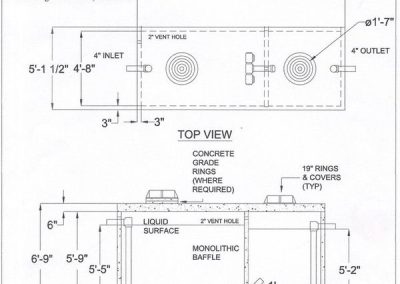

- 2400 SERIES ~ 2000 GALLON GREASE TRAP SINGLE BAFFLE

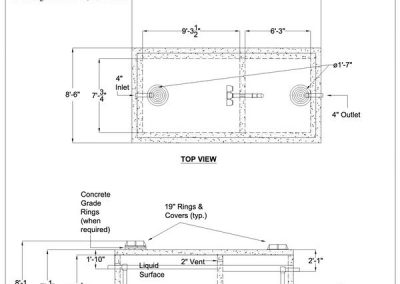

- 2400 SERIES ~ 3000 GALLON GREASE TRAP SINGLE BAFFLE

- HANDSET SERIES ~ 4000 GALLON GREASE TRAP SINGLE BAFFLE

- HANDSET SERIES ~ 5000 GALLON GREASE TRAP SINGLE BAFFLE

North Texas Plumbing installs Concrete Grease Traps made by PRECON Environmental Products

PRECON Environmental Products, LLC is the leader in per-engineered environmental products. Products are cataloged with standard features as shown on specification material. However, these products are often furnished to meet specific engineering requirements, and have special features and arrangements. In such cases, handling and installation procedures may vary slightly depending upon the actual type of construction. It is recommended that a company representative be consulted in each unique situation.

Codes and Installation

Local codes and regulations should supersede all recommendations made by PRECON Environmental Products, LLC and its representatives, and the appropriate authorities should be consulted before installation is made. Where an apparent conflict of code requirements and manufacturer recommendations or standard design exists, the assistance of a company representative should be requested. In almost every instance, PRECON Environmental Products, LLC will be able to make modifications necessary to comply with local codes, jurisdictions and interpretations, if notified prior to actual fabrication or upon order placement.

Field Preparation

The customer or his contractor shall prepare the excavation to the proper depth using dimensional data and weights from approved submitted drawings.

Call to confirm excavation dimensions and crane requirements.

All excavations should be shored or stepped back in accordance to OSHA recommendations.

A level base within the excavation and a minimum of twelve (12) inches of clearance on all sides of the unit is required. The depth of the base and the material shall meet the specifications and requirements for the type of soil at the setting location (consult with design engineer for base specifications).

All field excavation and preparation is the sole responsibility of the customer/contractor.

Unit will be delivered and placed in the excavation by PRECON Environmental Products, LLC or its representatives, when accessible for crane truck. The crane operator will perform rigging and setting the unit. It will be necessary for the customer/contractor to furnish the required labor to install the joint sealant and assist our crane operator with the installation. Back-fill is the sole responsibility of the owner/contractor.

Backfill

After the unit is set, the excavation should be completely back-filled immediately and prior to filling with water. The back-fill material shall meet the specifications and requirements for setting location (consult with design engineer for back-fill specifications). It is recommended that back-fill material be on site at the time of delivery. Two methods of back-fill are:

1. With material excavated placed in (1) one foot lifts and compacted and tamped to original density or per owner/engineer’s requirements.

2. Bank sand in (2) two foot lifts and compacted or water-jetted per owner/engineer’s requirements.

Testing (for tanks)

If project specifications require testing of tanks, use the following testing procedure. After completing the piping, the unit shall be properly back-filled. Fill the tank with water to the normal operating level. Record this level and let stand for 24 hours. Recheck the water level. A 5% or less variance is generally acceptable. Note that precast concrete tanks are designed for below grade installation with an earthen back-fill. DO NOT fill tanks with water until the tanks are properly back-filled. Filling tanks prior to back-filling may cause abnormal stresses and may result in leakage and/or damage to the tanks and may void the manufacturer’s warranty.

Drainage (for vaults)

Precast Concrete Meter and Back Flow Vaults that are installed below ground level may be drained by installing a 6” pea gravel or sand bed under the vault. The sump opening in the vault bottom allows rainwater and condensate to percolate to the ground below. This will also prevent up-lift of vault in the event of a flood. Grease traps in Weatherford. Grease traps in DFW Airport. Sample wells in DFW Airport.

- 3500 SERIES ~ 500 GALLON GREASEE INTERCEPTOR

- 3500 SERIES A ~ 1000 GALLON GREASE INTERCEPTOR

- 3500 SERIES ~1500 GALLON GREASE INTERCEPTOR SINGLE BAFFLE

- 2400 SERIES ~ 2000 GALLON GREASE INTERCEPTOR SINGLE BAFFLE

- 2400 SERIES ~ 3000 GALLON GREASE INTERCEPTOR SINGLE BAFFLE

- HANDSET SERIES ~ 4000 GALLON GREASE INTERCEPTOR SINGLE BAFFLE

- HANDSET SERIES ~ 5000 GALLON GREASE INTERCEPTOR SINGLE BAFFLE