Medical Gas Piping Installation in Dallas Fort Worth Area

Dallas Medical Gas Piping Installation Plumber

North Texas Plumbing is a commercial plumber service that specializes in medical gas installation plumbing services for both new construction and renovation of hospitals, veterinary clinics and surgical offices, surgery centers, dental facilities, emergency rooms and all other medical gas piping applications. North Texas Plumbing is fully licensed and insured for medical gas work. We can custom engineer the right medical gas system for your facility and complete the job from design to completion.

Medical Gas Piping Installation Experts in Dallas, Fort Worth and all across Texas

From hospitals to dentist offices, surgical centers and assisted living facilities we provide expert medical gas piping installation solutions in the Dallas Fort Worth Metroplex and all over Texas.

Specialty Commercial Plumbing Services in Fort Worth, Dallas and DFW Mid Cities

- Hospitals

- Medical Offices

- Health Care Facilities

- Emergency Room

- Veterinary Offices

- Veterinary Surgical Centers

- Operating Rooms

- Hybrid OR

Medical Gas Piping Installation

- Oxygen Piping

- Nitrous Oxide Piping

- Oxygen Pipe Welding

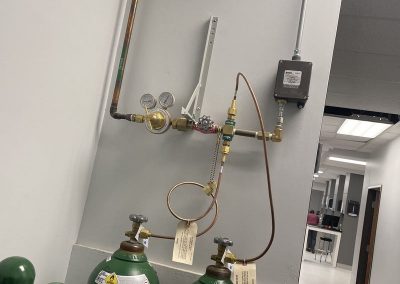

- Medical Gas Manifold Installation

- Medical Air Compressor Installation

- Medical Vacuum Installation

- Take-offs & Engineering

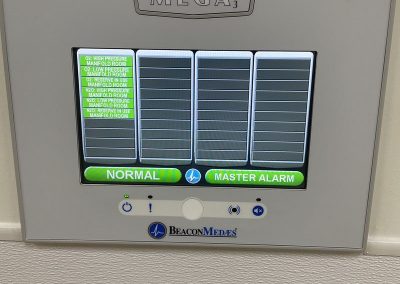

- Med Gas Outlet, Alarm, Zone Valve Installation

Medical gas piping installation service Dallas Fort Worth Metroplex & Mid Cites

Medical Gas Installers?

Medical gas installers are specialist plumbers trained and certified in installing medical gas piping systems. Our medical gas installers are are specifically certified by the State of Texas as installers for medical gas. Only licensed medical gas installation plumbers should install medical gas pipeline systems. North Texas Plumbing specializes in medical gas piping installation for new construction as well as renovations and repairs.

- Medical Gas Plumbing

- Medical Gas Piping Installation

- Medical gas supply

- Medical Gas Piping Installation Endorsement

- Medical Gas Installation NFPA 99

- Medical gas piping system

- Nitrous oxide

- Oxygen

Medical Gas Plumbing requires specialty grade copper that is used to plumb medical gas systems. Medical gas plumbers and installers are equivalent terms. Plumbing medical gas systems is similar to other types of plumbing and requires running pipe through floors, ceilings, and walls.

Medical gas piping installations use two types of copper piping; Type K (thicker and heavier) and Type L (thinner copper wall), which both meet NFPA 99 standards for positive pressure medical gas installations. Copper piping is always used to deliver medical grade gases from a utility room where they are stored in tanks to rooms where they are needed within a medical facility, veterinarian office, hospital or surgical center.

Medical gas supply systems in hospitals and other healthcare facilities are utilized to supply specialized gases and gas mixtures to various parts of the facility. Products handled by such systems typically include:

Oxygen

Medical air

Nitrous oxide

Nitrogen

Carbon dioxide

Medical vacuum

Waste anaesthetic gas disposal (US) or anaesthetic gas scavenging system (ISO)

Source equipment systems are generally required to be monitored by alarm systems at the point of supply for abnormal (high or low) gas pressure in areas such as general ward, operating theatres, intensive care units, recovery rooms, or major treatment rooms. Equipment is connected to the medical gas pipeline system via station outlets (US) or terminal units (ISO).

Medical gas systems are commonly color coded to identify their contents, but as coding systems and requirements (such as those for bottled gas) vary by jurisdiction, the text or labeling is the most reliable guide to the contents. Emergency shut-off valves, or zone valves, are often installed in order to stop gas flowing to an area in the event of fire or substantial leak, as well as for service. Valves may be positioned at the entrance to departments, with access provided via emergency pull-out windows.

Contents

1 Oxygen

2 Medical air

3 Nitrous oxide

4 Nitrogen

5 Instrument air/surgical air

6 Carbon dioxide

7 Medical vacuum

8 Waste anaesthetic gas disposal/anaesthetic gas scavenging system

9 Medical gas mixtures

10 References

11 External links

Oxygen

BeaconMedaes oxygen, vacuum, and medical air medical gas supply outlets

Oxygen may be used for patients requiring supplemental oxygen via mask. Usually accomplished by a large storage system of liquid oxygen at the hospital which is evaporated into a concentrated oxygen supply, pressures are usually around 345–380 kPa (50.0–55.1 psi),[1][2] or in the UK and Europe, 4–5 bar (400–500 kPa; 58–73 psi).[3] This arrangement is described as a vacuum insulated evaporator or bulk tank.[4] In small medical centers with a low patient capacity, oxygen is usually supplied by a manifold of multiple high-pressure cylinders. In areas where a bulk system or high-pressure cylinder manifold is not suitable, oxygen may be supplied by an oxygen concentrator. However, on site production of oxygen is still a relatively new technology.

Medical air

Medical air is compressed air supplied by a special air compressor, through a dryer (in order to maintain correct dew point levels), and distributed to patient care areas by half hard BS:EN 13348 copper pipe and also use isolation ball valve for operating the services of compressed air 4 bar. It is also called medical air 4 bar. In smaller facilities, medical air may also be supplied via high-pressure cylinders. Pressures are maintained around 345–380 kPa (50.0–55.1 psi). If not used correctly it can be harmful to humans.

Nitrous oxide

Nitrous oxide is supplied to various surgical suites for its anaesthetic functions during preoperative procedures. It is delivered to the hospital in high-pressure cylinders and supplied through the Medical Gas system. Some bulk systems exist, but are no longer installed due to environmental concerns and overall reduced consumption of nitrous oxide.

Nitrogen

Nitrogen is typically used to power pneumatic surgical equipment during various procedures, and is supplied by high-pressure cylinders. Pressures range around 1.2 MPa (170 psi) to various locations.

Instrument air/surgical air

Like nitrogen, instrument air is used to power surgical equipment. However, it is generated on site by an air compressor (similar to a medical air compressor) rather than high-pressure cylinders. Early air compressors could not offer the purity required to drive surgical equipment. However, this has changed and instrument air is becoming a popular alternative to nitrogen. As with nitrogen, pressures range around 1.2 MPa (170 psi). UK systems are supplied at 11 bar (1.1 MPa; 160 psi) to the local area and regulated down to 7–8 bar (700–800 kPa; 100–120 psi) at point of use.

Carbon dioxide

Typically used for insufflation during surgery, and also used in laser surgeries. System pressures are maintained at about 345 kPa (50.0 psi), UK 4 bar (400 kPa; 58 psi). It is also used for certain respiratory disorders. It contains 5 percent.[clarification needed]

Medical vacuum

Medical vacuum in a hospital supports suction equipment and evacuation procedures, supplied by vacuum pump systems exhausting to the atmosphere. Vacuum will fluctuate across the pipeline, but is generally maintained.

Waste anaesthetic gas disposal/anaesthetic gas scavenging system

Waste anaesthetic gas disposal, or anaesthetic gas scavenging system, is used in hospital anaesthesia evacuation procedures. Although it is similar to a medical vacuum system, some building codes require anaesthetic gases to be scavenged separately. Scavenging systems do not need to be as powerful as medical vacuum systems, and can be maintained around −50 to −65 kPa (−380 to −490 mmHg; −15 to −19 inHg).

Medical gas mixtures

There are many gas mixtures used for clinical and medical applications. They are often used for patient diagnostics such as lung function testing or blood gas analysis. Test gases are also used to calibrate and maintain medical devices used for the delivery of anaesthetic gases. In laboratories, culture growth applications include controlled aerobic or anaerobic incubator atmospheres for biological cell culture or tissue growth. Controlled aerobic conditions are created using mixtures rich in oxygen and anaerobic conditions are created using mixtures rich in hydrogen or carbon dioxide. Supply pressure is 4 bar (400 kPa; 58 psi).

Two common medical gas mixtures are entonox and heliox.

Medical gas plumbing (aka Med Gas Pipe Systems ) requeires specific certification from the State of Texas’ State Board of Plumbing Examiners.

FROM: Texas State Boaord of Plumbing Examiners

“There are three different endorsements that may be added to a Master Plumber, Journeyman Plumber, or Plumbing Inspector License. They include:

Medical Gas Piping Installation Endorsement;

Multipurpose Residential Fire Protection Sprinkler Specialist Endorsement; and

Water Supply Protection Specialist Endorsement.

Eligibility Requirements

Medical Gas Piping Installation

You may take the Medical Gas Piping Installation Endorsement Examination if:

you are currently licensed as a Master Plumber, Journeyman Plumber, or Plumbing Inspector in Texas; and

you have completed a 24-hour training course approved by the TSBPE.

Multipurpose Residential Fire Protection Sprinkler Specialist

You may take the Multipurpose Residential Fire Protection Sprinkler Specialist Endorsement Examination if:

you are currently licensed as a Master Plumber, Journeyman Plumber, or Plumbing Inspector in Texas; and

you have completed a 24-hour training course approved by the TSBPE or you hold a current RME-General or RME-Dwelling License issued by the State Fire Marshal.

Water Supply Protection Specialist

You may take the Water Supply Protection Specialist Endorsement Examination if:

you are currently licensed as a Master Plumber, Journeyman Plumber, or Plumbing Inspector in Texas; and

you have completed a 24-hour training course approved by the TSBPE.

Scope of Work Permitted

Medical Gas Piping Installation

A Journeyman or Master Plumber who holds a Medical Gas Piping Installation Endorsement may install piping used solely to transport gases for medical purposes under the supervision of a Responsible Master Plumber who also holds the endorsement. A Plumbing Inspector who holds a Medical Gas Piping Installation Endorsement may inspect installations of medical gas vacuum piping.

PLEASE NOTE: The American Society of Sanitary Engineers (ASSE) offers a national accreditation for Medical Gas Verifiers. The TSBPE does not regulate Medical Gas Verifiers. ASSE also offers accreditation for Medical Gas Installers, and Medical Gas Maintenance. Neither of these accreditations is recognized in Texas.

Multipurpose Residential Fire Protection Sprinkler Specialist

A Journeyman or Master Plumber who holds a Multipurpose Residential Fire Protection Sprinkler Specialist Endorsement may install a multipurpose residential fire protection sprinkler system in a one or two-family dwelling under the supervision of a Responsible Master Plumber who also holds the endorsement. A Plumbing Inspector who holds a Multipurpose Residential Fire Protection Sprinkler Specialist Endorsement may inspect installations of these sprinkler systems.

Water Supply Protection Specialist

A Journeyman or Master Plumber who holds a Water Supply Protection Specialist Endorsement may install, service, or repair plumbing associated with the treatment, use, and distribution of rainwater to supply a plumbing fixture, appliance, or irrigation system under the supervision of a Responsible Master Plumber who also holds the endorsement. A Journeyman or Master Plumber who holds a Water Supply Protection Specialist Endorsement may also perform a customer service inspection certification for a public drinking water system pursuant to 30 Tex. Admin. Code Chapter 290. A Plumbing Inspector who holds a Water Supply Protection Specialist Endorsement may inspect plumbing installed for the treatment, use, and distribution of rainwater to supply a plumbing fixture, appliance, or irrigation system.”

The National Fire Protection Association standard 99 establishes criteria for levels of health care services or systems based on risk to the patients, staff, or visitors in health care facilities to minimize the hazards of fire, explosion, and electricity. NFPA 99 Health Care Facilities Code 5.1.10.11.10.2 states: “Any medical gas plumber involved in the installation of medical gas piping systems, piped vacuum systems, and/or supporting components for manifolds, zone valves, alarms, and outlets, must have an ASSE 6010 Installer certificate.”

NFPA 99 Medical gas installations refers to installation of Medical Gas Pipeline Systems for piped medical gases (oxygen, medical air, N2O (nitrous oxide) and other medical gasses) using only medical grade copper piping and medical equipment including medical gas outlets, alarm panels and oilless air compressors.

Texas Administrative Code

TITLE 25 HEALTH SERVICES

PART 1 DEPARTMENT OF STATE HEALTH SERVICES

CHAPTER 131 FREESTANDING EMERGENCY MEDICAL CARE FACILITIES

SUBCHAPTER G PHYSICAL PLANT AND CONSTRUCTION REQUIREMENTS

RULE §131.143 Construction Requirements for a New Facility

(h) Piping systems and plumbing fixture requirements. All piping systems and plumbing fixtures shall be designed and installed in accordance with the requirements of the National Standard Plumbing Code Illustrated published by the National Association of Plumbing-Heating-Cooling Contractors (PHCC), 2003 edition, and this paragraph. The National Standard Plumbing Code may be obtained by writing or calling the PHCC at the following address or telephone number: Plumbing-Heating-Cooling Contractors, P.O. Box 6808, Falls Church, Virginia 22046; telephone (800) 533-7694.

(1) Piping systems.

(A) Water supply piping systems. Water service pipe to point of entrance to the building shall be brass pipe, copper tube (not less than type M when buried directly), copper pipe, cast iron water pipe, galvanized steel pipe, or approved plastic pipe. Domestic water distribution system piping within buildings shall be brass pipe, copper pipe, copper tube, or galvanized steel pipe. Piping systems shall be designed to supply water at sufficient pressure to operate all fixtures and equipment during maximum demand.

(i) Each water service main, branch main, riser, and branch to a group of fixtures shall be equipped with accessible and readily identifiable shutoff valves. Stop valves shall be provided at each fixture.

(ii) Backflow preventers (vacuum breakers) shall be installed on hose bibs, laboratory sinks, janitor sinks, bedpan flushing attachments, and all other fixtures to which hoses or tubing can be attached. Connections to high hazard sources, e.g., X-ray film processors, shall be from a cold water hose bib through a reduced pressure principle type backflow preventer (RPBFP).

(iii) Flush valves installed on plumbing fixtures shall be of a quiet operating type, equipped with silencers.

(iv) Water heating equipment shall have sufficient capacity to supply water for all clinical needs based on accepted engineering practices using actual number and type of fixtures and for heating, when applicable.

(v) Hot water distribution system serving all patient care areas shall be under constant recirculation to provide continuous hot water at each hot water outlet.

(vi) Water temperatures shall be measured at hot water point of use or at the inlet to processing equipment. Hot water temperature at point of use for patients, staff, and visitors shall be in the range of 105 to 120 degrees Fahrenheit.

(vii) When potable water storage tanks (hot and cold) are used, the water shall be used and replenished. Domestic water storage tank(s) shall be fabricated of corrosion-resistant metal or lined with noncorrosive material. Water shall not be stored in tanks for future use unless the water is tested weekly for contaminates/bacteria.

(viii) Purified water distribution system piping shall be task specific and include, but not necessarily be limited to, polypropylene (PP), polyvinylidene fluoride (PVDF) or polyvinyl chloride (PVC) pipe. Final installed purified water system piping assemblies shall be UL approved and fully comply with applicable American Society for Testing and Materials (ASTM) Fire Resistant/Smoke Density requirements. The applicable documents are available from ASTM International, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, Pennsylvania 19428-2959.

(ix) Dead-end piping (risers with no flow, branches with no fixture) shall not be installed. In any renovation work, dead-end piping shall be removed. Empty risers, mains and branches installed for future use are permitted.

(B) Fire sprinkler systems. When provided, fire sprinkler systems shall comply with the requirements of NFPA 101, §9.7, Automatic Sprinklers and Other Extinguishing Equipment, and the requirements of this subparagraph. All fire sprinkler systems shall be designed, installed, and maintained in accordance with the requirements of NFPA 13, Standard for the Installation of Sprinkler Systems, 2002 Edition, and shall be certified as required by §131.147(c)(1)(C) of this title (relating to Construction, Inspection, and Approval of Project).

(C) Piped nonflammable medical gas and clinical vacuum systems. Piped nonflammable medical gas and clinical vacuum system shall be designed, installed, and certified in accordance with the requirements of NFPA 99, §5.1 for Level 1 Piped Systems and the requirements of this subparagraph.

(i) Nonflammable medical gas and clinical vacuum outlets shall be provided in accordance with Table 3 of §131.148(c) of this title.

(ii) Medical gas piping systems including source tanks and related piping shall be installed only by, or under the direct supervision of, a holder of a master plumber license or a journeyman plumber license with a medical gas piping installation endorsement issued by the Texas State Board of Plumbing Examiners.

Nitrous oxide, commonly known as laughing gas, nitrous, or nos, is a chemical compound, an oxide of nitrogen with the formula N2O. At room temperature, it is a colourless non-flammable gas, with a slight metallic scent and taste. At elevated temperatures, nitrous oxide is a powerful oxidiser similar to molecular oxygen.

Nitrous oxide has significant medical uses, especially in surgery and dentistry, for its anaesthetic and pain reducing effects. Its colloquial name, “laughing gas”, coined by Humphry Davy, is due to the euphoric effects upon inhaling it, a property that has led to its recreational use as a dissociative anaesthetic. It is on the World Health Organisation’s List of Essential Medicines, the safest and most effective medicines needed in a health system.

Oxygen storage methods include high-pressure oxygen tanks, cryogenics and chemical compounds. For reasons of economy, oxygen is often transported in bulk as a liquid in specially insulated tankers, since one liter of liquefied oxygen is equivalent to 840 liters of gaseous oxygen at atmospheric pressure and 20 °C (68 °F). Such tankers are used to refill bulk liquid-oxygen storage containers, which stand outside hospitals and other institutions that need large volumes of pure oxygen gas. Liquid oxygen is passed through heat exchangers, which convert the cryogenic liquid into gas before it enters the building. Oxygen is also stored and shipped in smaller cylinders containing the compressed gas; a form that is useful in certain portable medical applications.

Uptake of O2 from the air is the essential purpose of respiration, so oxygen supplementation is used in medicine. Treatment not only increases oxygen levels in the patient’s blood, but has the secondary effect of decreasing resistance to blood flow in many types of diseased lungs, easing work load on the heart. Oxygen therapy is used to treat emphysema, pneumonia, some heart disorders (congestive heart failure), some disorders that cause increased pulmonary artery pressure, and any disease that impairs the body’s ability to take up and use gaseous oxygen.

Treatments are flexible enough to be used in hospitals, the patient’s home, or increasingly by portable devices. Oxygen tents were once commonly used in oxygen supplementation, but have since been replaced mostly by the use of oxygen masks or nasal cannulas.

Hyperbaric (high-pressure) medicine uses special oxygen chambers to increase the partial pressure of O2 around the patient and, when needed, the medical staff. Carbon monoxide poisoning, gas gangrene, and decompression sickness (the ‘bends’) are sometimes addressed with this therapy. Increased O2 concentration in the lungs helps to displace carbon monoxide from the heme group of hemoglobin.

Highly concentrated sources of oxygen promote rapid combustion. Fire and explosion hazards exist when concentrated oxidants and fuels are brought into close proximity; an ignition event, such as heat or a spark, is needed to trigger combustion. Oxygen is the oxidant, not the fuel, but nevertheless the source of most of the chemical energy released in combustion.

Concentrated O2 will allow combustion to proceed rapidly and energetically.

Liquid oxygen spills, if allowed to soak into organic matter, such as wood, petrochemicals, and asphalt can cause these materials to detonate unpredictably on subsequent mechanical impact.

Please call today to schedule service 817-371-0709.

At Dallas Fort Worth Plumbing we are Medical Gas Piping installation commercial plumber specialists.

Dallas fort worth plumbing is your 24/7 365 day a year commercial plumbing service. At Dallas Fort Worth Plumbing we are dedicated to providing our customers with exceptional, punctual and professional service backed by our 100% satisfaction guarantee.